Rethinking concrete design and construction for a low-carbon future

Article content

November 3, 2025

Addressing the built environment’s carbon footprint requires not only innovating new building materials, but reconsidering how we use concrete. In 2022, KPMB partnered with an integrated design and engineering team for a research project aimed at reducing the carbon content of concrete using only widely available materials and scalable strategies.

By Kael Opie

The North American construction industry is built upon concrete’s endemic use for a reason: it’s a durable, versatile, and cost-effective material.

But making cement — concrete’s key ingredient — is exceptionally carbon intensive. Producing clinker from limestone and clay releases carbon through calcination, a chemical process whose extreme heat is typically fuelled by burning coal or natural gas. According to current estimates, cement production is responsible for a staggering 8 percent of global carbon emissions.

Despite the growing use of alternative materials in construction, concrete is unlikely to be replaced in the short or medium term. A low-carbon substitute that is equivalently scalable and cost effective has yet to be developed. Steel construction offers lower embodied emissions than concrete, roughly 25 percent according to one study, but its supply and fabrication reveal a similar energy and carbon emissions profile per kg/m². Mass timber holds immense promise but requires bespoke engineering and construction expertise and has yet to capture a significant market share.

With global building area expected to double by 2060, it’s imperative that we approach low-carbon construction on two fronts. First, we must continue developing and refining alternative low-carbon materials. Second, we need to work more effectively with the tools and materials we already have.

A collaboration between industry and academia

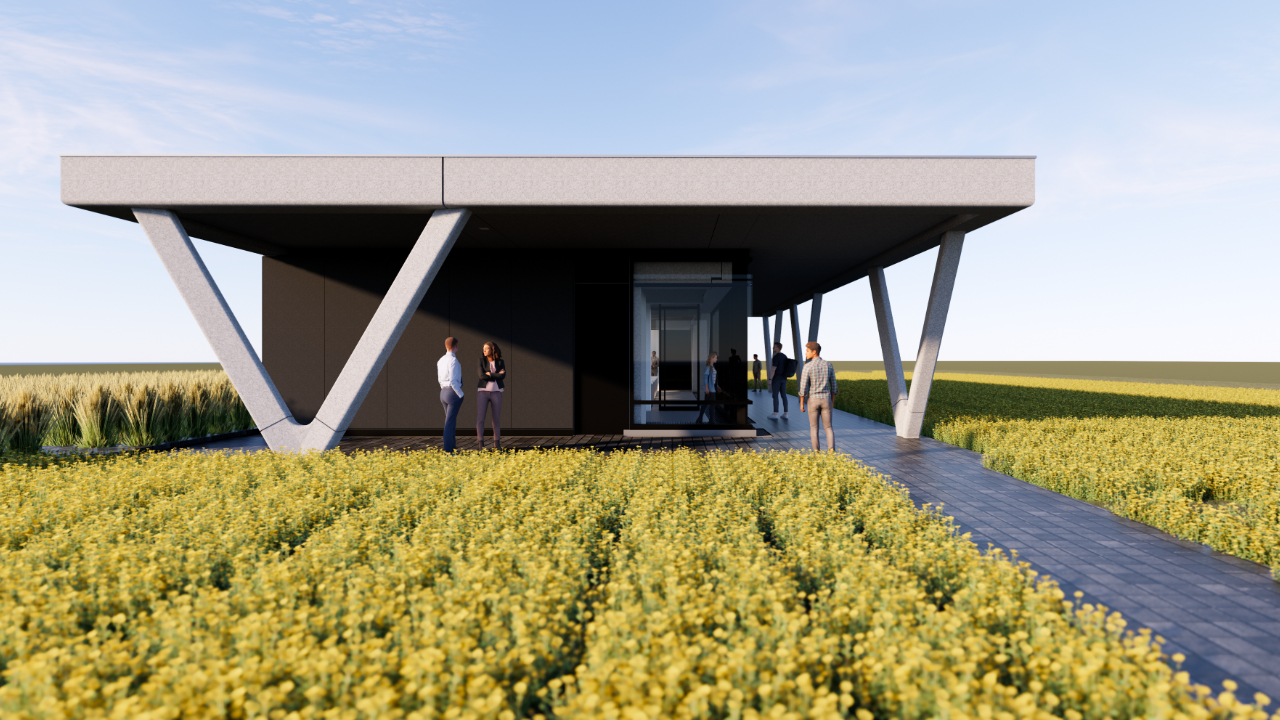

In 2022, Dr. Evan Bentz of the University of Toronto and Dr. Neil Hoult of Queen’s University invited KPMB to collaborate on the design of a new instructional facility for the City of Kingston’s Fire and Rescue Training Campus. While small in footprint, the project was large in ambition: the goal of its design was to reduce concrete’s carbon footprint using only conventional, affordable, and widely available materials and processes.

Through a series of collaborative workshops, an interdisciplinary research team, including Arup, AECON, Lafarge (now Amrize), Avenue Building Corporation, Modular Precast Systems, and Structurama, designed a concrete pavilion with an embodied carbon footprint that is 86 percent lower than an equivalent structure built with conventional methods.

The pavilion was designed as a low-carbon demonstration project for Kingston, Ontario.

The pavilion was designed as a low-carbon demonstration project for Kingston, Ontario.

Crucially, this strategy does not rely only on altering the recipe for concrete but instead reconsiders how the building structure is designed and engineered.

Conventional low-carbon concrete typically reduces cement content by using Supplementary Cementitious Materials (SCMs). The use of SCMs alone, however only reduce embodied carbon by up to 30 percent compared to a conventional mix.

More aggressive low-carbon concrete mixes, while commercially available, dramatically extend cure times. A standard 28 day cure period can balloon up to 56 or 91 days. This can create delays and logistical issues that raise costs, making aggressive low-carbon concrete mixes problematic and often impractical.

To establish a baseline condition, the pavilion structure was first designed using conventional cast-in-place beams, columns, flat slabs, and strip footings for a total of 86,000 kg of CO₂. By simply adjusting the concrete mix, the structure’s carbon content could be reduced by approximately 30 percent to 58,500 kg. Such results, while notable, were limited without changing tack.

Typical low-carbon concrete, which uses Supplementary Cementitious Materials (SCMs), can reduce concrete’s embodied carbon by approximately 30 percent without introducing scheduling issues.

Typical low-carbon concrete, which uses Supplementary Cementitious Materials (SCMs), can reduce concrete’s embodied carbon by approximately 30 percent without introducing scheduling issues.

To improve outcomes, our research team developed a three-step process to address these issues. Our strategy significantly reduced the estimated embodied carbon of the structural concrete, while preserving its material advantages of scalability and repeatability.

Step 1: Optimizing shapes

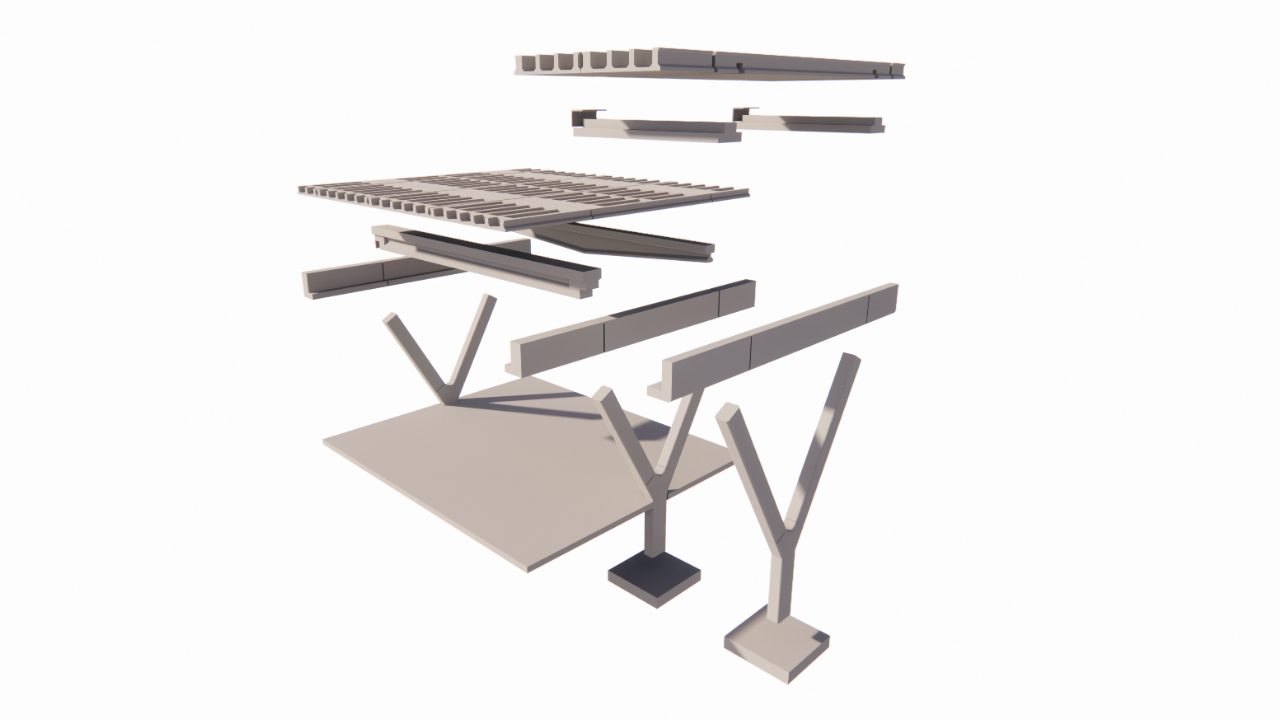

Digital analysis enabled the design team to rethink the pavilion’s elements, with critical feedback provided by Aecon and Avenue Building Corporation. Informed by the practical research and testing being undertaken by graduate students at Queen’s University and the University of Toronto, structurally unnecessary concrete mass was replaced with hollows and voids, while columns and footings were minimized through cantilevers and canted “V” supports. The concrete volume of some elements was reduced by 50 to 60 percent.

The shape of beams was optimized to reduce unnecessary concrete mass.

The shape of beams was optimized to reduce unnecessary concrete mass.

Applying these strategies to all component elements reduced the pavilion’s overall concrete volume from 246 to 147 m³ and reduced the overall carbon content to 51,000 kg — a 40 percent reduction, achieved without adjusting the concrete mix.

Once the overall volume of concrete was reduced, a low-carbon mix could be applied more effectively. A standard mix with a 30 percent carbon reduction lowered emissions further to an estimated 37,800 kg of CO₂, a cumulative 56 percent improvement over our conventional baseline design.

Step 2: Using precast methodologies

The primary trade-off with aggressive low-carbon mixes is substantially longer cure times. To address this, the team turned from a cast-in-place to precast concrete methodology. Because precast elements cure in controlled shop conditions, their use can help avoid construction delays — all while offering better strength, higher tolerances, and superior quality compared to their cast-in-place alternatives.

By using precast elements, the scheduling impact of long cure times was effectively removed from the equation and allowed an exceptionally low-carbon concrete mix to be applied. A 70 percent low-carbon mix resulted in approximately 15,000 kg of CO₂, a cumulative 82 percent reduction from baseline.

Shape–optimized beams were tested to failure at the Smith Engineering School’s hydraulic testing lab at Queen’s University.

Shape–optimized beams were tested to failure at the Smith Engineering School’s hydraulic testing lab at Queen’s University.

Step 3: Erecting pre-cast elements

Working closely with Structurama and Modular Precast, the team developed a series of unique precast elements. By using this “kit of parts” approach, site erection time can be dramatically reduced and formwork, including the conventional and time-consuming re-shore process required by cast-in-place concrete, can be virtually eliminated. This reduction in time on site comes with other logistical and carbon-related benefits, such as reduced on-site heating during cold weather.

Factoring these savings, we estimate that the pavilion’s carbon content could be reduced further to 12,000 kg of CO₂, a cumulative 86 percent reduction.

Scalability

Importantly, this process does not require the invention and application of new technologies. Once a system of precast elements has been developed and the concrete strategy refined, this three-step approach can be effectively applied across multiple projects with repeatable and predictable outcomes. As a result, it is especially well suited to oft-repeated forms, such as mid- and low-rise housing typologies.

While developing and refining these strategies will likely require additional time and fees in the design and engineering stages, it will undeniably save time on site, reduce overall capital costs, and realize substantial carbon dividends — all without the use of new materials.

Shop-formed under ideal conditions, a “kit of parts” can dramatically reduce construction time compared to a cast-in-place strategy.

Shop-formed under ideal conditions, a “kit of parts” can dramatically reduce construction time compared to a cast-in-place strategy.

The power of an integrated design process

A truly integrated design process proved essential to the pavilion’s unique design methodology. Achieving meaningful carbon reductions through this iterative process demanded input from a range of experts, including architects, engineers, fabricators, and constructors. Had any one of these players been responsible for the carbon reduction strategy on their own, the results would have been muted.

Addressing carbon emissions is a shared responsibility that requires cooperation and commitment from all participants. Only through a truly integrated and open-minded design approach can we collectively realize the transformative change that the building industry needs.

Kael Opie is a principal at KPMB Architects with expertise in advanced building technologies, energy efficiency, and sustainable strategies. He was the project architect for the first LEED Platinum-certified commercial project in the Toronto area and a project architect for one of the most energy-efficient towers in the world.

Related News

KPMB to host BAIDA’s first Externship program

February 18, 2026Four new associates join KPMB’s leadership

February 5, 2026Mitchell Hall to share adaptive reuse insights at BUILDEX Vancouver

January 27, 2026

)

)

)